Visiting Test and Measurement Technology

06. 11月 2025

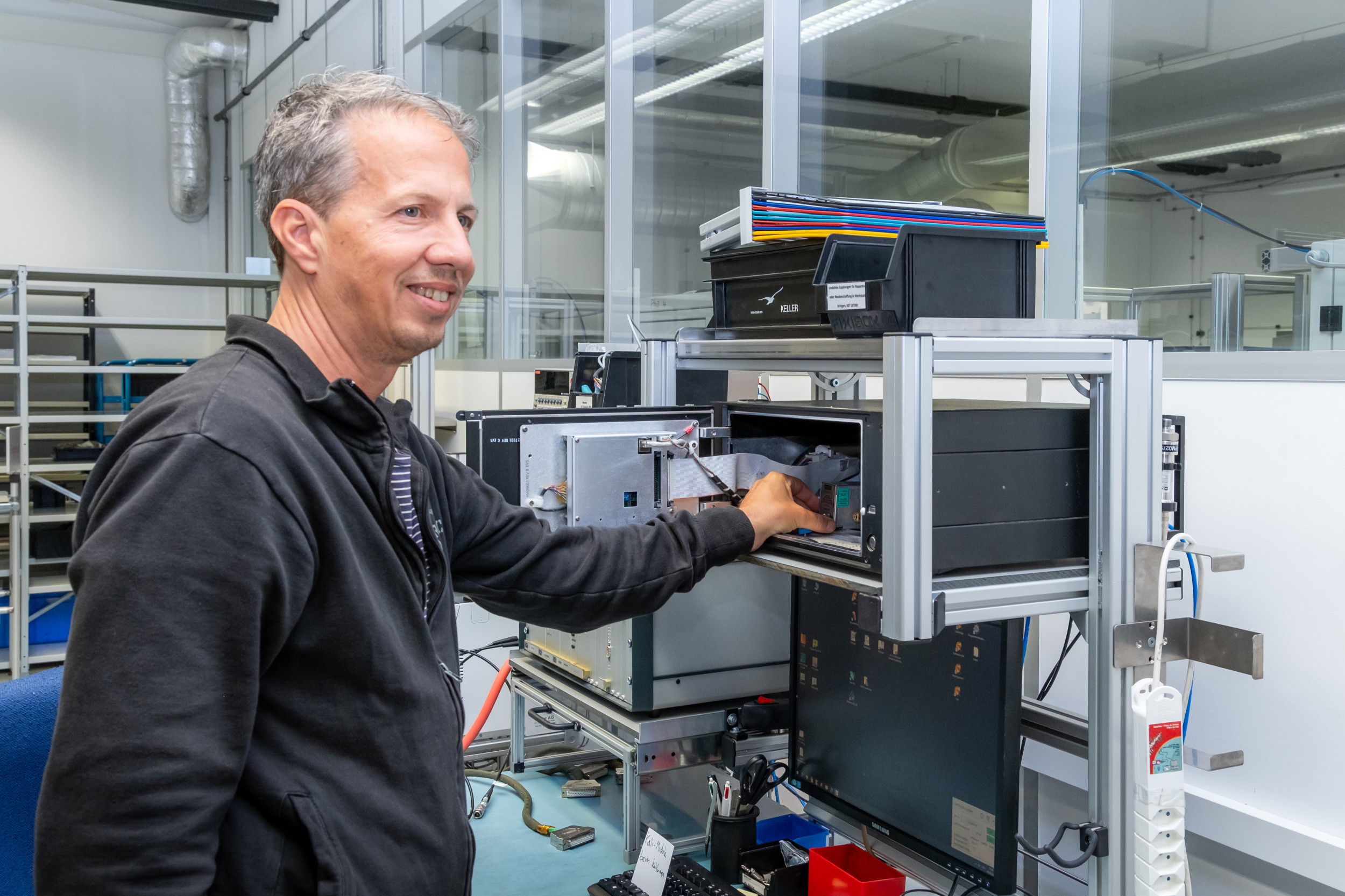

Precision is crucial for our pressure sensors, as even the smallest deviations can have a major impact. To ensure that our measuring devices work reliably at all times, DMT's mobile testing laboratory visits us once a year. The specialists check our devices on site and adjust them if necessary. This allows us to avoid long downtimes and ensure smooth production processes.

In this article, we take you on a tour of their mobile laboratory, show you the work of our calibrators in detail, and explain why we have been relying on our partnership with DMT for over ten years.

Testing devices and their purpose

Our pressure sensors undergo several quality controls during manufacture. They are calibrated using a reference device and their accuracy is precisely checked and documented.

We use around 80 calibrators with a total of 260 pressure modules for these test measurements, 124 of which are used exclusively for high-precision sensors. Our quality assurance department regularly checks the calibrators with accredited differential pressure transmitters (reference instruments). In addition, the DMT test laboratory checks the calibrators used for high-precision measurements.

The mobile testing laboratory from DMT

DMT is a laboratory accredited by DAkkS (German Accreditation Body). In addition to its stationary laboratory in northern Germany, it has a unique mobile testing laboratory: a container that is transported by truck directly to the customer's premises and set up there.

This special container is designed to create constant conditions for precise measurements. Floor heating, air conditioning, and an airlock prevent temperature or pressure fluctuations from distorting the results. Before testing begins, the container is precisely leveled. This is an essential prerequisite for the use of the high-precision test scales inside.

This is how a visit to us works

Once the laboratory is set up, testing can begin. Each calibrator usually contains three to four measuring modules with different pressure ranges, for example barometer, 3.5 bar, 11 bar, 70 bar, or 210 bar.

To keep production running, we remove the measuring modules one by one and take them to the lab. That's where calibration takes place:

- Comparison of the modules with the reference devices

- Adjustment if the results deviate from the tolerances

- Re-examination to confirm the correction

In most cases, the modules are just within the specifications and only require minor adjustments. However, around ten percent – mostly in the low-pressure range – exceed the specifications and require more extensive corrections.

The mobile laboratory remains on site for one week at a time, from Friday to Friday. Since we do not produce on weekends, the laboratory can make optimal use of this time. Several modules with the same pressure ranges can be tested one after the other without having to set up the measuring station each time.

Occasionally, an entire calibrator may fail, usually a high-pressure device with 200 or 400 bar. In these cases, it is not the measuring module that is affected, but the internal control system. These devices are sent to the stationary laboratory in northern Germany for repair.

Long-standing cooperation

DMT launched its mobile testing laboratory in October 2010. Just one year later, it was used for the first time at our premises in Winterthur. Since then, regular visits have become part of our routine.

With the number of our calibrators increasing by 20 percent in the last two years alone, our cooperation with DMT is more important to us than ever. It ensures that our devices work reliably and that our production runs smoothly.

Dipl.-Ing. (FH) Heiko Bergfeld

Managing Director DMT Druckmesstechnik GmbH«For over 15 years, we have enjoyed a trusting partnership with KELLER Pressure – from pressure controllers to calibration services. Together, we pursue a single goal: maximum quality and minimum downtime. Thank you for allowing DMT-GmbH to be part of your success story – and we hope to remain so for a long time to come!»

Our long-standing partnership with DMT enables us to ensure maximum precision without having to accept interruptions in production. The mobile testing laboratory saves time, effort, and costs – making it a central, indispensable component of our quality assurance system.